Service

Maintenance package compact

Maintenance

LAVAIR maintains the system once a year according to the check list. Depending on the operation and requirements of the system, it can also be done several times a year. A system-specific maintenance book is provided and kept. It documents all maintenance work that has been carried out, as well as any defects were found. All separately commissioned repair work is also described.

Hygiene inspection

LAVAIR carries out the hygienic inspection required for the safe operation of the system every 2 years in accordance with the requirements of VDI 6022. The test is carried out by qualified and trained technicians and the results are documented in the maintenance book. The hygiene inspection must be ordered separately.

Reduced hourly rates

In Case of troubleshooting ore refurbishment LAVAIR grant his service customers a reduced hourly rate, which is valid at the time of deployment.

Repair exclusive

The repair or replacement of wearing parts or spare parts (outside the warranty) is not included in this maintenance package. We will provide you a corresponding offer if required. As maintenance customer you also benefit from our very advantageous prices for standard spare parts.

Spare parts service

If a replacement of any components on your system is required, we offer you a first-class spare parts service for LAVAIR products as well as for third-party products. We purchase spare parts that are not kept in our warehouse directly from the manufacturer.

Contract period

The standard contract period is 2 years and can be terminated 3 months before the end of the contract period. About the maintenance interval / scope, we are happy to respond to your requests.

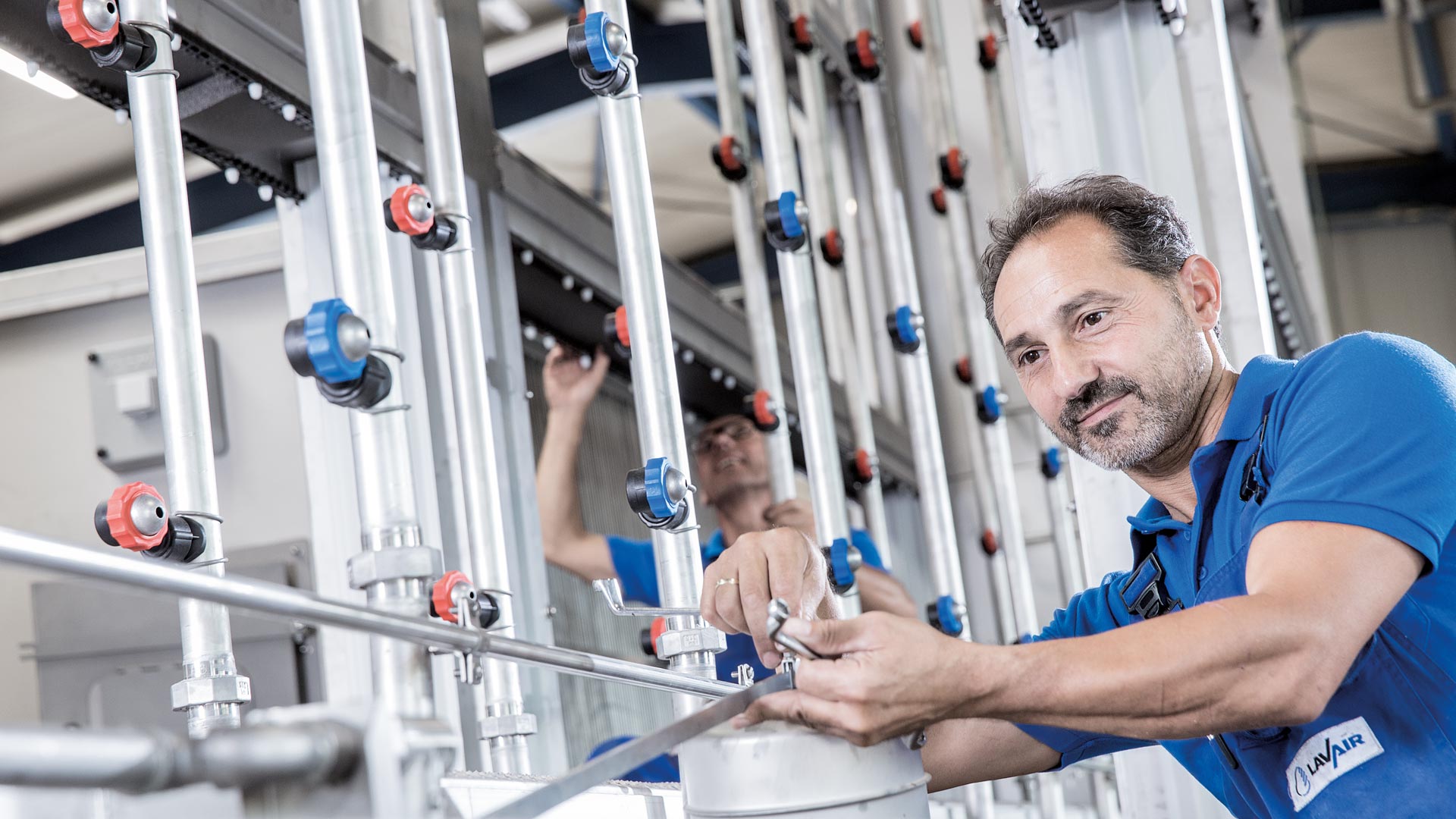

Assembly and Commissioning

Our experienced and well-trained engineers and service technicians will assemble your humidifier on-site and commission it, setting all parameters so as to enable the humidifier to work reliably and efficiently.

We recommend that assembly be carried out by our employees, particularly if the humidifier is delivered in disassembled parts.

Following the commissioning, you will receive a detailed record of the settings that have been made. Ideally, such commissioning will be combined with training of your employees, in which general advice on operating the system, regular maintenance as well as functional and hygiene checks will be given.

Your employees will also receive extensive training on how the system components work and how to handle them. This will ensure that your humidifier is always used and maintained in the best possible manner.

This, to us, is an essential prerequisite for energy-efficient operation coupled with low maintenance costs. Not least, lasting care of the humidifier will ensure that the service life and value retention of the system extend beyond the average useful life.

Zurück

Weiter

Refurbishment

If the existing air humidifier develops functional or hygienic defects, refurbishment is unavoidable.

If the humidifier tank is still in good condition or is at least capable of refurbishment, the system can usually be repaired and thereby brought up to date by replacing the faulty built-in parts. If, however, a partial refurbishment cannot be expected to bring about the desired effect in terms of service life, system availability and maintenance overhead, complete refurbishment is often the most cost-effective solution.

Our range of services includes:

- Energy-based and functional analysis of the existing air humidifier.

- Proposals for a partial refurbishment or replacement of the system are then derived from this appraisal, taking cost-efficiency criteria into account.

Partial refurbishment of the air humidifier:

- Refurbishment of leaky humidifier tanks (GRP)

- Replacement of eliminator and rectifier profiles

- Replacement of nozzles

- Adapting the device configuration to changes in air volume flows and humidity requirements

- Retrofitting/remodelling the humidifier (including third-party products) in line with the current Hygiene Directive VDI 6022

Replacement of the air humidifier:

- Measurement of the unit geometry and housing flanges & analysis of the insertion procedure

- Dismantling of the old system & assembly of the new unit within a time frame specified by the operator

- Handover report, induction and training of the maintenance personnel

Our experts will be pleased to provide you with a tailor-made refurbishment concept following an on-site meeting.