Willkommen bei LAVAIR

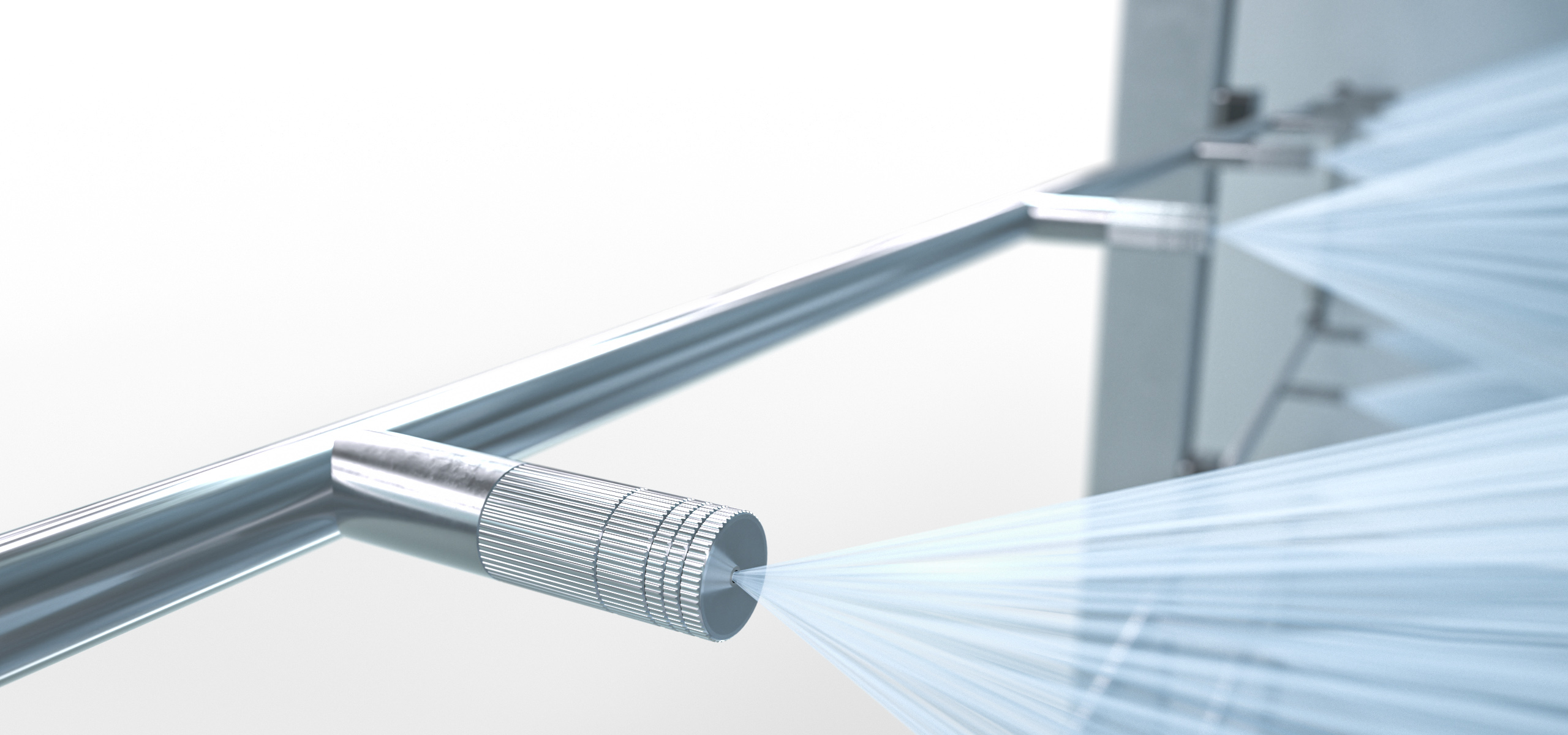

Lavair wurde bereits 1996 gegründet und hat sich schnell zum Marktführer als Hersteller von Luftwäscher entwickelt. Neben den klassischen Anwendungen von Luftwäschern lag schon früh der Fokus auf Befeuchtungssysteme, die Neu und innovativ sind. Seit jeher zählt Lavair somit zu den international führenden Systemanbietern von Befeuchterlösungen für lufttechnische Anlagen.

Als ein Unternehmen der familiengeführten Herrmann-Gruppe, welche mit über 100 Mitarbeitern und Partnern weltweit erfolgreich tätig ist, zeichnen wir uns durch eine hochmoderne Edelstahl-Bearbeitung, innovativen Entwicklungsgeist und traditionsreiche Unternehmenskultur aus. Unterstützt werden wir dabei bereits seit Beginn an durch internationale Vertriebspartner, welche unseren Kunden hinsichtlich Produktauswahl, Wartung, Sanierung und Instandhaltung beratend zur Seite stehen.

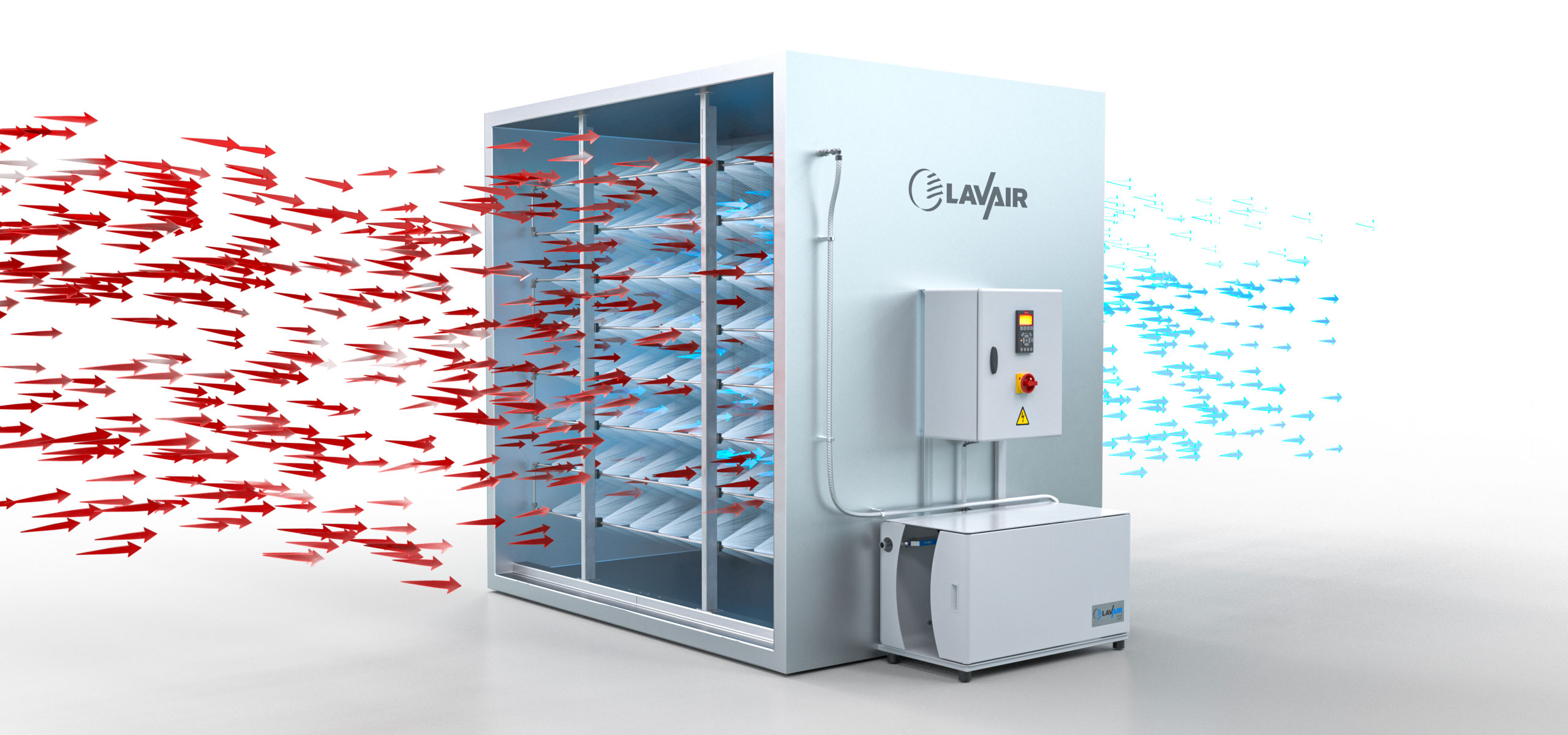

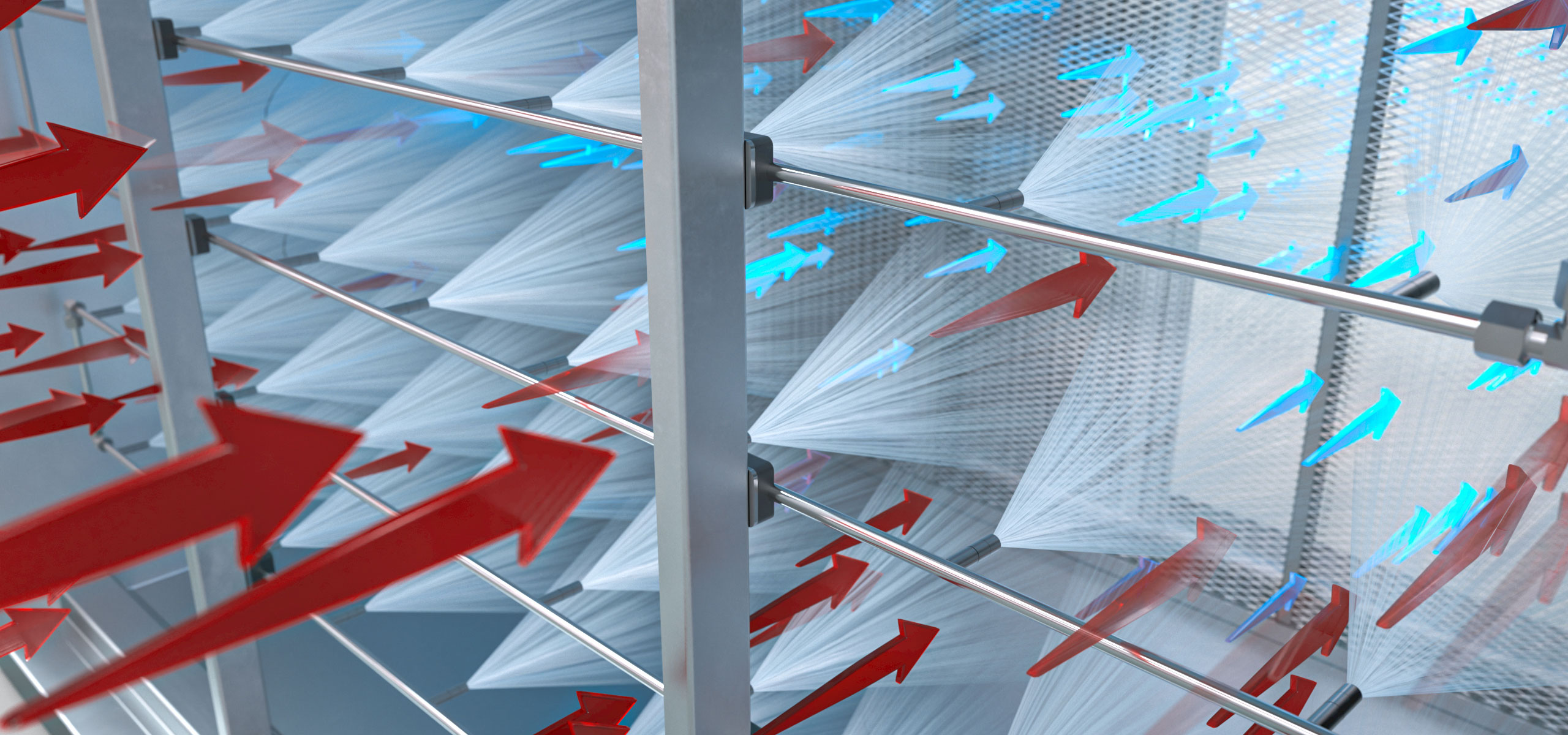

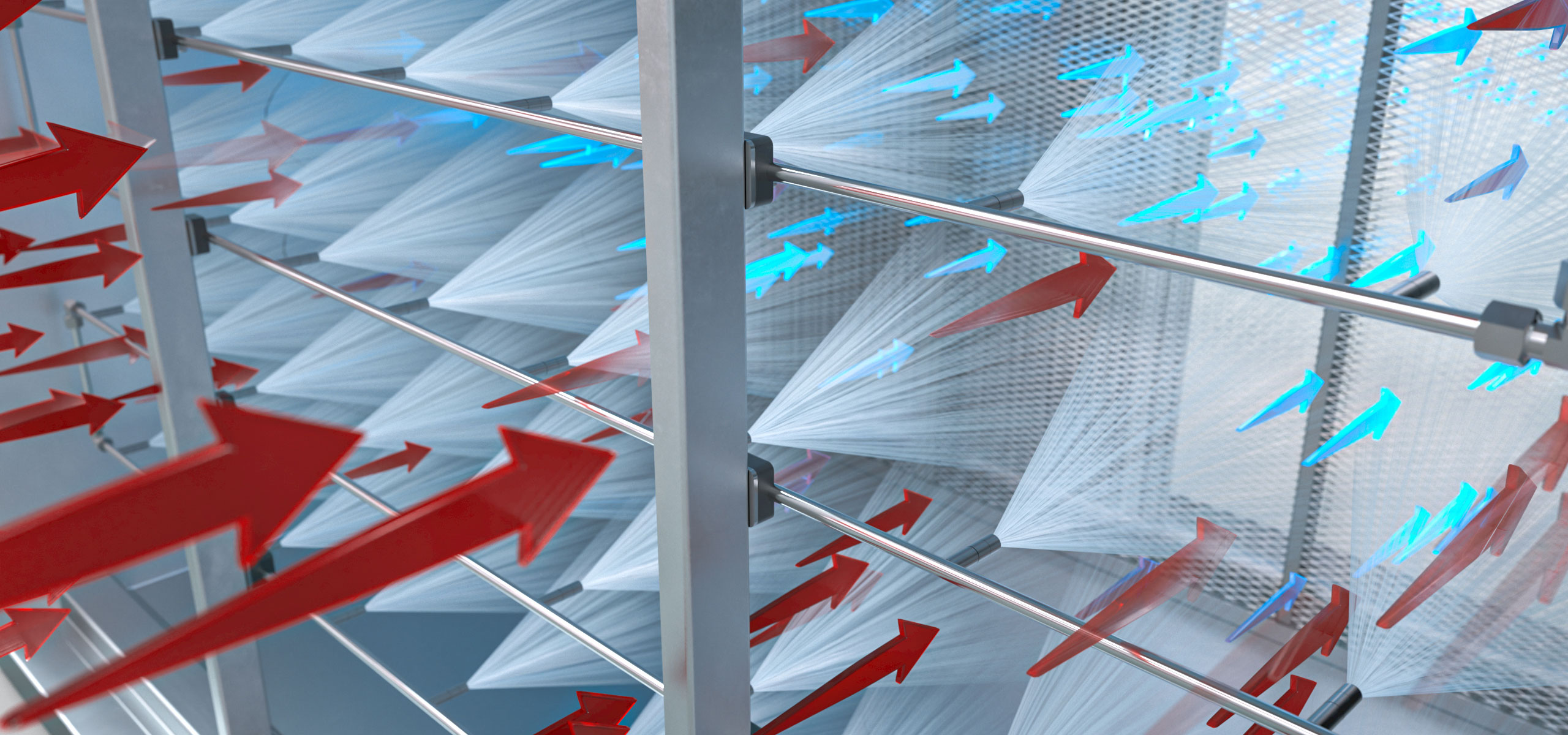

An unseren Produktionsstandorten in Aach am Bodensee und in China werden alle Systeme individuell auf kundenspezifische Wünsche und Abmessungen angepasst. Unsere Systeme finden dabei Ihren Einsatz für Luftvolumenströme von 200 m³/h bis zu 2.000.000 m³/h zur Luftkonditionierung und -reinigung, z.B. in Lackieranlagen der Automobil- und Möbelindustrie, der Komfortgebäudelüftung, der Reinraumtechnik, der Biofiltration sowie in der Abluftreinigung unterschiedlichster Applikationen. Eine individuelle Anpassung an die Anforderungen unserer Kunden hinsichtlich Geometrie und prozesstechnische Vorgaben wie Luftkondition am Befeuchtereintritt, Befeuchtungswirkungsgrad, Regelgenauigkeit, Luftgeschwindigkeit, Hygieneanforderungen, etc. sind dank des Knowhows unserer Mitarbeiter sowie unseres flexiblen Maschinenparks jederzeit möglich.

Höchste Qualität, kurze Lieferzeiten und maximale Kundenzufriedenheit – Lavair-Werte seit 1996

Designed for natural air.

Befeuchtungssysteme seit 2020

Luft durchströmen die seit 2020

gebauten Systeme

Projekte seit 2020

– einfache PID-Regleranpassung

– Bestätigung der Wartungsdurchführung

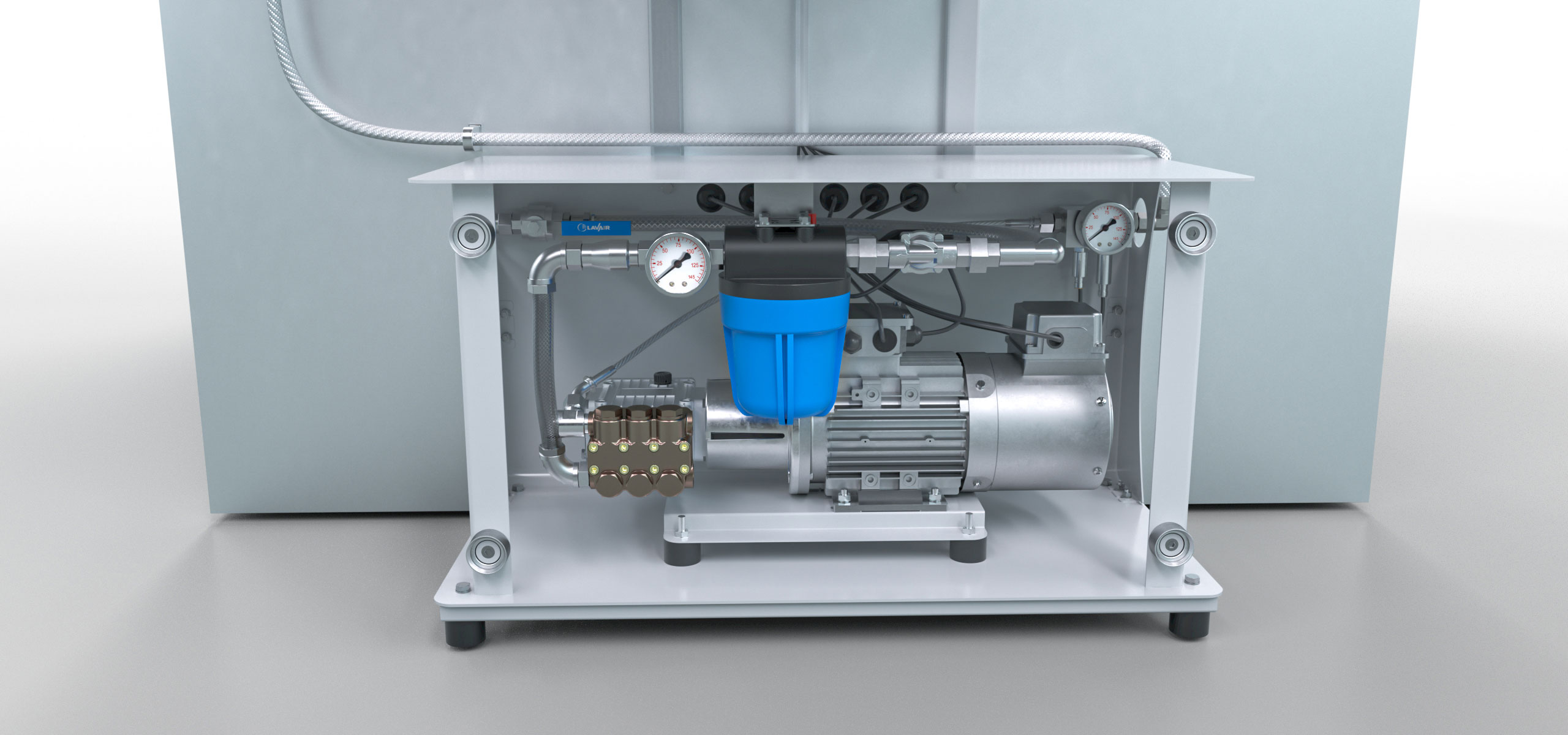

Schwingungsisolierte Rahmenkonstruktion sowie abnehmbare Front zur leichten Zugänglichkeit

Branchen

Automobilindustrie

Prozessklimatisierung

Befeuchtung großer Luftvolumenströme bei präziser Regelbarkeit der Auffeuchtung.

Gebäudetechnik

Gebäudeklimatisierung

Kostengünstige Befeuchtersysteme für ein

angenehmes Raumklima bei geringen

Betriebskosten und niedrigem

Wartungsaufwand.

Stahlindustrie

Abluftreinigung

Effiziente Abscheidung von Öl- und Emulsionsnebeln aus der Herstellung von Stahlblechen in Walzwerken.

Fleischverarbeitung / Tierfutterherstellung

Abluftreinigung

Mechanische / chemische Auswaschung von

Schadstoffen aus der Abluft sowie

Luftbefeuchtung für eine nachgeschaltete

biologische Reinigungsstufe

(Biofiltersystem).

Halbleiterfertigung

Reinraumtechnik

Waschstufe nach dem Mikrofilter zur

Reduzierung der Anzahl luftgetragener

Teilchen und Fremdgase auf ein absolutes

Minimum.

Textilindustrie

Abluftreinigung

Auswaschung von Stäuben bei der

Herstellung synthetischer Fasern und

Fliesstoffe.

„Top Qualität, hochzufriedene Kunden, kurze Lieferzeiten, hochinnovative Produkte.

Dafür steht Lavair,

dafür stehen wir“

Stephan u. Ralph Herrmann, Vorstand Lavair

Branchen

Automobilindustrie

Prozessklimatisierung

Befeuchtung großer Luftvolumenströme bei präziser Regelbarkeit der Auffeuchtung.

Gebäudetechnik

Gebäudeklimatisierung

Kostengünstige Befeuchtersysteme für ein

angenehmes Raumklima bei geringen

Betriebskosten und niedrigem

Wartungsaufwand.

Fleischverarbeitung / Tierfutterherstellung

Abluftreinigung

Mechanische / chemische Auswaschung von

Schadstoffen aus der Abluft sowie

Luftbefeuchtung für eine nachgeschaltete

biologische Reinigungsstufe

(Biofiltersystem).

Stahlindustrie

Abluftreinigung

Effiziente Abscheidung von Öl- und Emulsionsnebeln aus der Herstellung von Stahlblechen in Walzwerken.

Halbleiterfertigung

Reinraumtechnik

Waschstufe nach dem Mikrofilter zur

Reduzierung der Anzahl luftgetragener

Teilchen und Fremdgase auf ein absolutes

Minimum.

Textilindustrie

Abluftreinigung

Auswaschung von Stäuben bei der

Herstellung synthetischer Fasern und

Fliesstoffe.

News

Neuer Vertriebspartner für die Türkei

Wir freuen uns, eine neue Partnerschaft für den Vertrieb unserer adiabatischen Luftbefeuchtungssysteme in der Türkei verkünden zu können. Die Firma

ISH Frankfurt 13. – 17.03.2023

Lavair war in diesem Jahr zum ersten Mal als Austeller auf der führenden Branchenmesse ISH in Frankfurt am Main vertreten.

Lavair stellt aus – ISH Frankfurt 13. – 17.03.2023

Lavair wird in diesem Jahr auf der führenden Branchenmesse ISH vertreten sein und seine innovativen Produkte und Dienstleistungen präsentieren. Die

Neuer Vertriebspartner für die Türkei

Wir freuen uns, eine neue Partnerschaft für den Vertrieb unserer adiabatischen Luftbefeuchtungssysteme in der Türkei verkünden zu können. Die Firma

ISH Frankfurt 13. – 17.03.2023

Lavair war in diesem Jahr zum ersten Mal als Austeller auf der führenden Branchenmesse ISH in Frankfurt am Main vertreten.

Lavair stellt aus – ISH Frankfurt 13. – 17.03.2023

Lavair wird in diesem Jahr auf der führenden Branchenmesse ISH vertreten sein und seine innovativen Produkte und Dienstleistungen präsentieren. Die

Lavair zu Besuch auf der Chillventa 2022

Vom 11. bis 13. Oktober 2022 trafen sich die Experten der Klima-Branche aus aller Welt auf der Chillventa in Nürnberg.

Unsere Referenzen